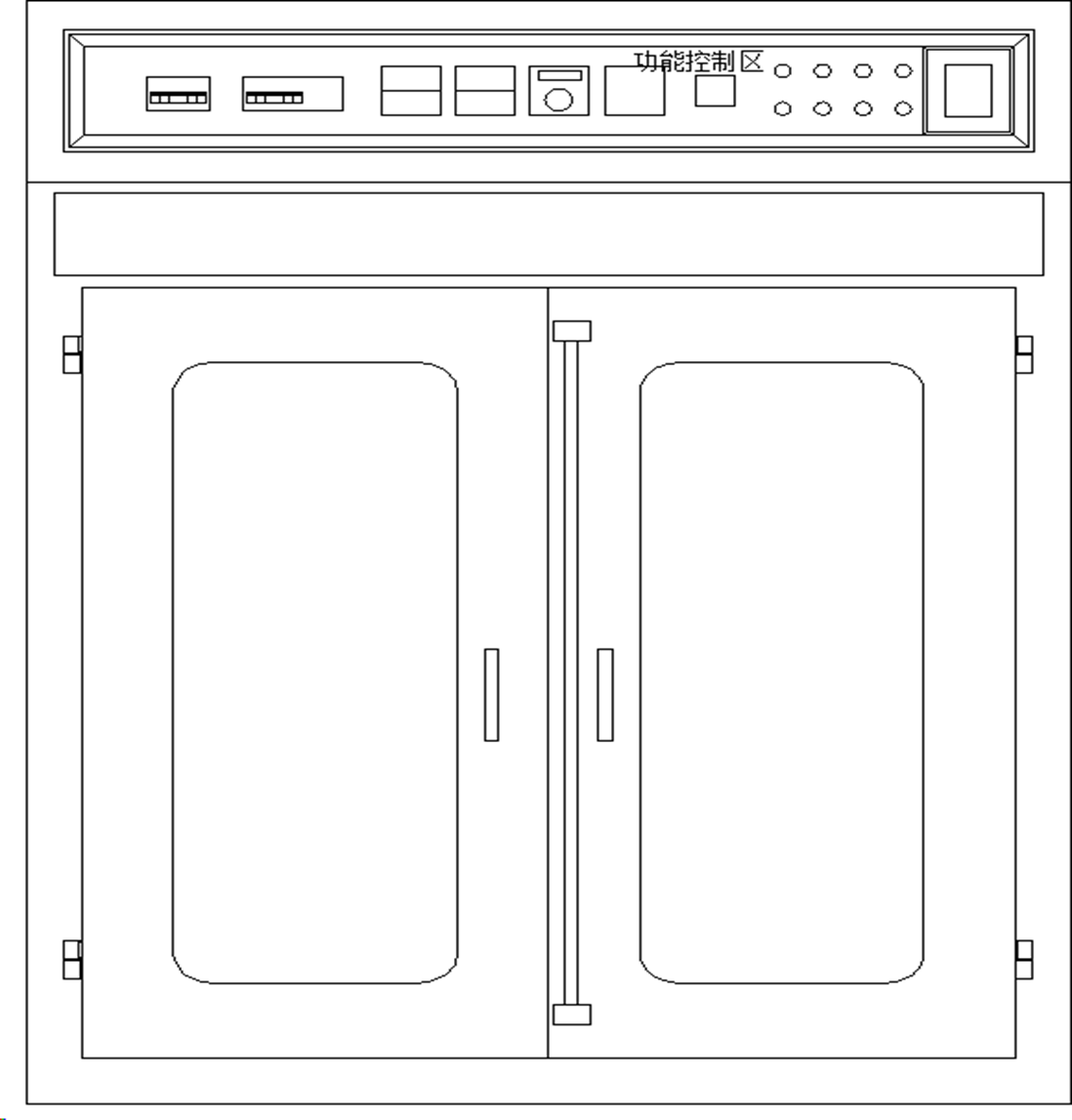

1、Exterior

Carton size: 180X207X50CM (WxHxD) Studio size: 150X135X35CM(WxHxD)

Cabinet performance introduction:

Heating box part:

1. External 1.2mm cold plate bending forming.

2. The inner dan is bent by 1.2mm galvanized sheet.

3. The thermal insulation layer is 80mm, and the imported aluminum silicate rock wool is used for insulation.

4. The wind motor adopts one Taiwan Oakli vertical extended shaft motor, with a power of 1HP, 380V, equipped with a 10.5-inch fan blade for air supply, and an over-temperature forced exhaust fan

5. Adopt left and right air supply type, from the left and right air outlets, and the upper top sucks air

6. Oven base plate (for mounting circuit boards)

7. The oven door is equipped with a visible glass observation window, and the glass specification is 300*1000mm

Heating system:

It is heated by ceramic heating element, the power is 9KW, and the normal temperature is adjustable at -70°C. The control accuracy ± 0.1°C, the fluctuating temperature ±1°C, and the uniformity temperature in the chamber is ±5°C at no load (at constant temperature).

Electrical Parts:

1. The RKC intelligent digital display temperature control meter for temperature control meter has PID self-tuning (automatic optimization).

2. CHINT AC contactor for control heating

3. PT100 platinum probe for temperature probe

4. Additional electrical appliances: over-temperature meter, phase protector, ammeter, voltmeter, CHINT AC contactor, relay, switch, indicator light,

(important electrical appliances are joint ventures, others are CHINT brands)

5. Function: with over-temperature alarm power-off, temperature timing, alarm power-off at the time, (fully automatic control)

Surface paint: The color of the fuselage is computer white paint.

2、Device

The sedan is connected to 380V with a minimum of 10 square meters of wires, with a total power of 6KW, a test peak of 6KW when the machine is turned on, and an average peak value of 4KW during the test.

3. Purpose

With the addition of an SSD RDT interface, you can directly test M.2 SATA and

M.2 PCIE SSDs without going through board transfer, simplifying the steps of board assembly and transfer, improving production efficiency, and reducing labor costs

Fourth, temperature control system

Manual control to turn on and off the temperature control, integrated precise up and down circulation temperature control system, can set the over- temperature temperature. At the beginning of the test, the heating is turned on, and it only takes 10 minutes to quickly rise from normal temperature to 70 degrees Celsius and remain constant at 70 degrees, and the heat dissipation mode is automatically activated after the temperature exceeds during the RDT test, and the hot air in the box is pumped to the outside, so that the temperature quickly drops back to the set temperature.

5. Test process

1. The SSD is inserted into the RDT board, the light does not turn on when the disk is not recognized, the RDT flashes when it is working, and the RDT end LED is solid or off, depending on the SSD scheme.

2. Run the RDT test automatically after plugging in the disk

3. After the RDT test is completed, the RDT end LED will be on or off, and the flash will be defective.

6. RDT test board

1. Each board has 13 ports of 2.5-inch SATA ports and M.2 M Key ports, and 936 ports per box

2. Each port is powered independently, using high-power Schottky two-pole isolation, with strong anti-interference ability

3. Each port is equipped with 3 LEDs, which are 5V/3.3V power indicator and RDT working indicator. When the product is not affixed with LEDs, it can be judged by the RDT working indicator of the RDT test board.

4,The RDT board is powered by a 12V switching power supply, and each port is equipped with a high-current DC-DC IC to convert to 5V to ensure stable power supply. Up to 4TB disks can be measured.

7. Comparison of the advantages of multi-functional RDT boxes

M.2 interface SSD test line comparison: estimated by 100K/month test capacity

|

Traditional RDT box |

Multifunctional RDT box |

Advantages of multi- functional RDT box |

|

|

Layout space usage |

500 mouths per box |

936 mouths per box |

Small footprint, saving space and increasing RDT |

|

output |

|||

|

Personnel operation |

To run PCIE/M.2 SATA and other products, you need to install an adapter board to run RDT |

There is no need to install an adapter plate |

The operation is simple, reduces man-hours, and can save the manpower of traditional loading and turning, which is 1/3 less than that of traditional boxes |

|

Labor costs |

0.3 |

0.2 |

30% decrease |

|

Annual labor cost |

250,000 |

200,000 |

Cost savings of 50,000 yuan |

|

Improve yields |

The transfer plate is used and stacked many times, which is easy to be damaged and has poor contact, resulting in misjudgment |

Reduce the transfer plate, test and fix, not easy to damage |

Reduce RDT mispositives and reduce secondary RDT |

|

Capacity expansion |

There are many equipment, many personnel, more land occupation, more links, and poor capacity expansion capacity. |

Less equipment, fewer personnel, fewer links, Strong capacity expansion capacity |

The two machines occupy an area of 3 square meters, and 4 sets of traditional RDT boxes are topped |