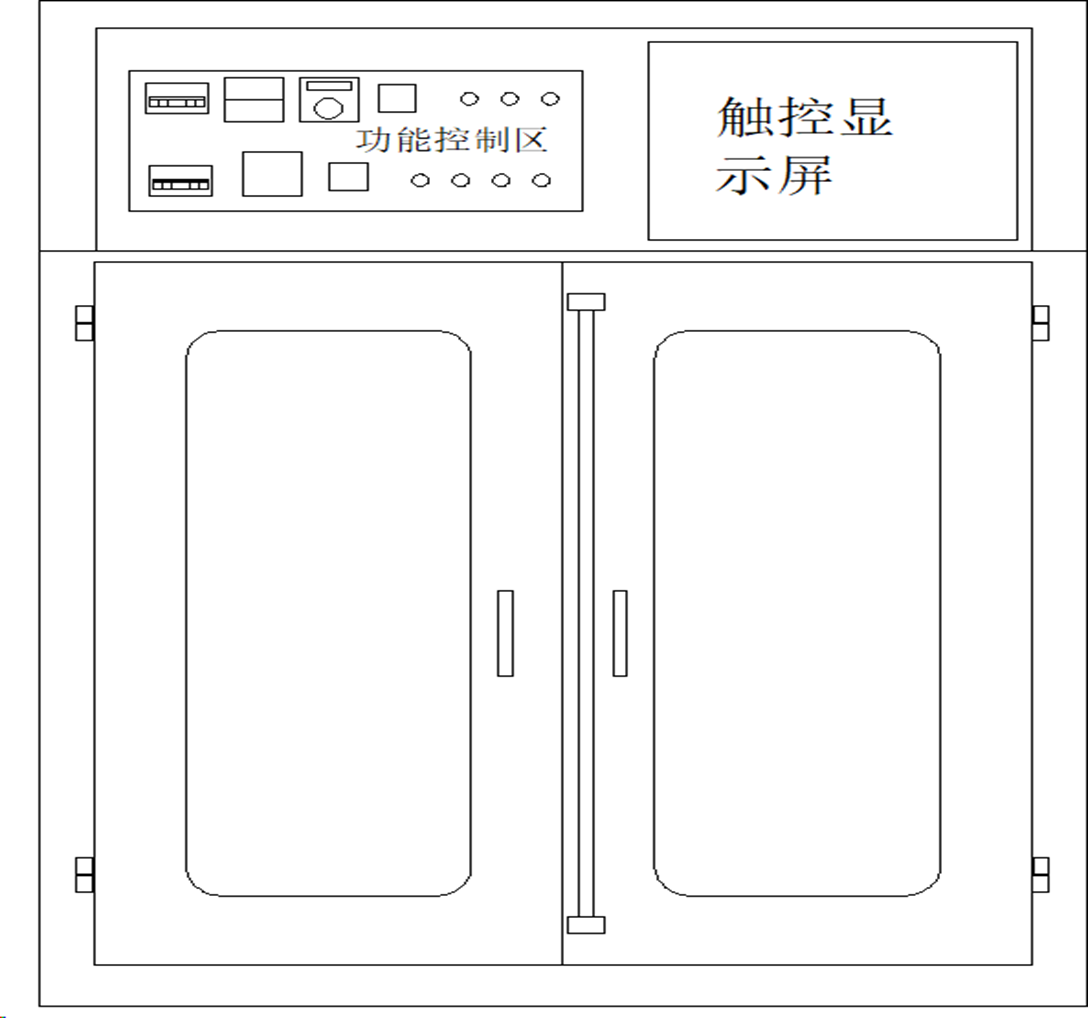

OUTER BOX SIZE:180 X 207 X 101.6CM (WxHxD) STUDIO SIZE:150 X 135 X 35CM(WxHxD)

Cabinetperformance introduction:

Heating box part:

1. External 1.2mm cold plate bending forming.

2. The inner dan is bent by 1.2mm galvanized sheet.

3. The thermal insulation layer is 80mm, and the imported aluminum silicate rock wool is used for insulation.

4. The wind motor adopts one Taiwan Oakli vertical extended shaft motor, with a power of 1HP, 380V, equipped with a 10.5-inch fan blade for air supply, and an over-temperature forced exhaust fan

5. Adopt left and right air supply type, from the left and right air outlets, and the upper top sucks air

6. The back of the oven is 350mm deep and divided into 4 layers

7. The size of the rear box of the oven is 1500mm wide * 350mm deep according to the height of the oven, divided into 4 layers, with 4 pallets of 350*1500*15mm

Heating system:

It is heated by ceramic heating element, the power is 9KW, and the normal temperature is adjustable at -70°C. The control accuracy ± 0.1°C, the fluctuating temperature ±1°C, and the uniformity temperature in the chamber is ±5°C at no load (at constant temperature).

Electrical Parts:

1. The RKC intelligent digital display temperature control meter for temperature control meter has PID self-tuning (automatic optimization).

2. CHINT AC contactor for control heating

3. PT100 platinum probe for temperature probe

4.Additional electrical appliances: over-temperature meter, phase protector, ammeter, voltmeter, CHINT AC contactor, relay, switch, indicator light, (important electrical appliances are joint ventures, others are CHINT brands)

5. Function: with over-temperature alarm power-off, temperature timing, alarm power-off at the time, (fully automatic control)

Surface paint: The color of the fuselage is computer white paint.

2、Device

The sedan is connected to 380V with a minimum of 10 square meters of wires, with a total power of 6KW, a test peak of 6KW when the machine is turned on, and an average peak value of 4KW during the test.

3. Purpose

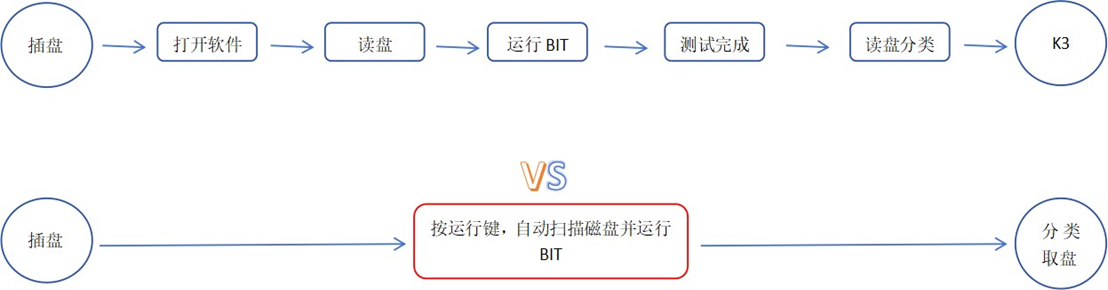

Simplify the test steps, reduce the manual operation process, visually judge NG products, reduce the fault tolerance rate in the production process, start the synchronous test of 24 interface SSD disks with one click, and complete the BIT process test and judgment without human intervention during the test process.

Reduce manual operation steps and improve efficiency

Fourth, equipment configuration

1. 10th Gen PC Window10 64-bit, dual-core CPU, 4th Gen DDR 8GB.

2. Each SATA interface is independently supplied with DC 5V/4A (switching power supply 12 to 5V).

3. A single computer supports 24 SATA3 2.5-inch ports, and 32 built-in computers can test 768 tablets.

5. Temperature control system

Manual control to turn on and off the temperature control, integrated precise up and down circulation temperature control system, can set the over- temperature temperature. At the beginning of the test, the heating is turned on, and it only takes 10 minutes to quickly rise from normal temperature to 70 degrees Celsius and remain at 70 degrees, and the heat dissipation mode is automatically activated after the temperature exceeds during the BIT test, and the hot air in the box is pumped to the outside, so that the temperature quickly drops back to the set temperature.

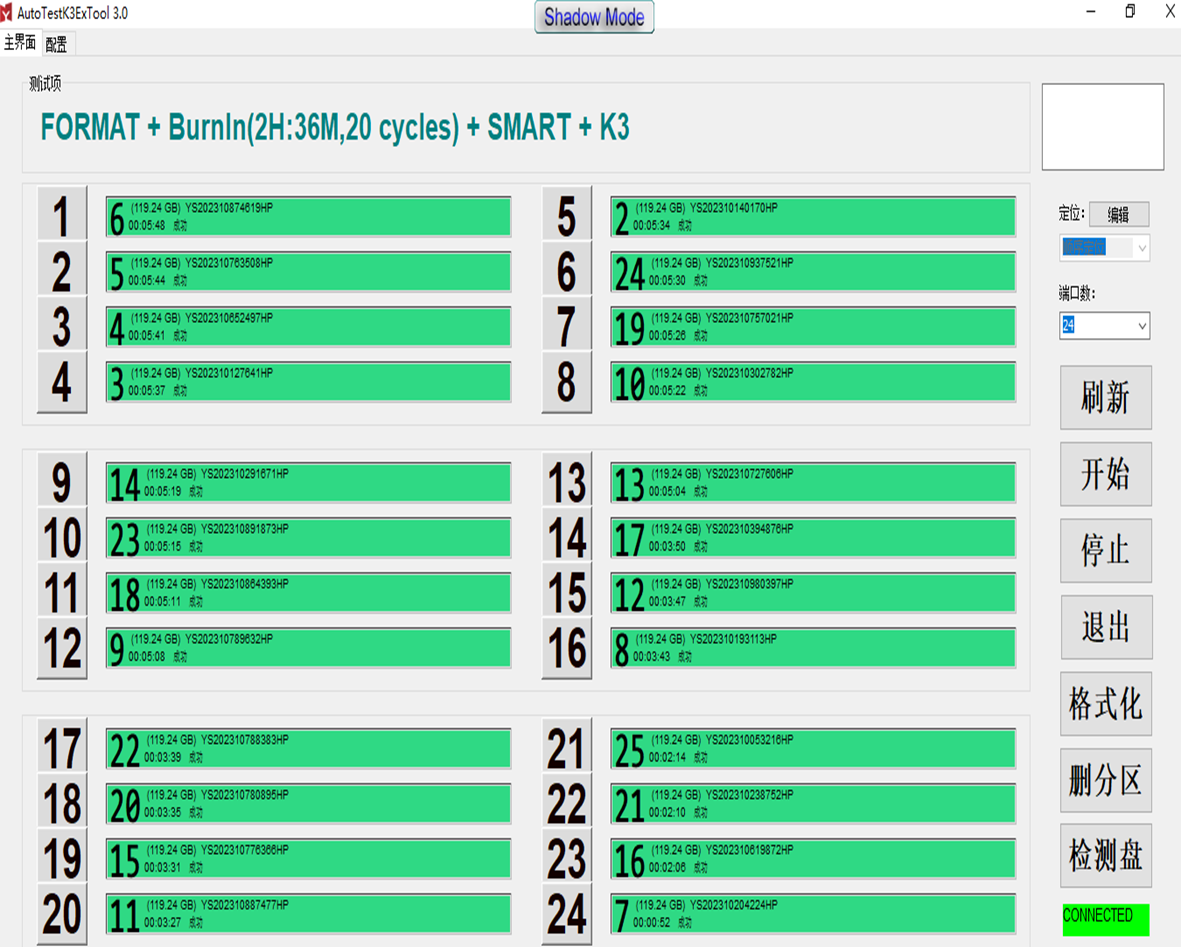

Sixth, the

1. The SSD is plugged into the handset computer, the disk is not recognized, and the green LED light flashes brightly.

2. Click the run button on the BIT burn-in board, and the software scans 24 interfaces by itself, reads the disk, and automatically runs the BIT test

3. After the BIT test is completed, the LED light on the BIT board shows that green is good and red is bad.

4. It can be set to automatically skip the K3 function, and run the K3 action automatically after running the BIT (only for a micro solution)

7.BIT test board

1. 24 ports 2.5 inch SATA port

2. Each port is powered independently.

3. Each port is equipped with 3 color LED lights (red, green, blue), the

recognition disk is a solid green light, the non-recognition disk is not lit, the BIT is a red light prompt, and the speed test is not normal blue light.

4. The BIT test board is equipped with a power on and off button and a computer indicator, which can be turned on and off through the beta version.

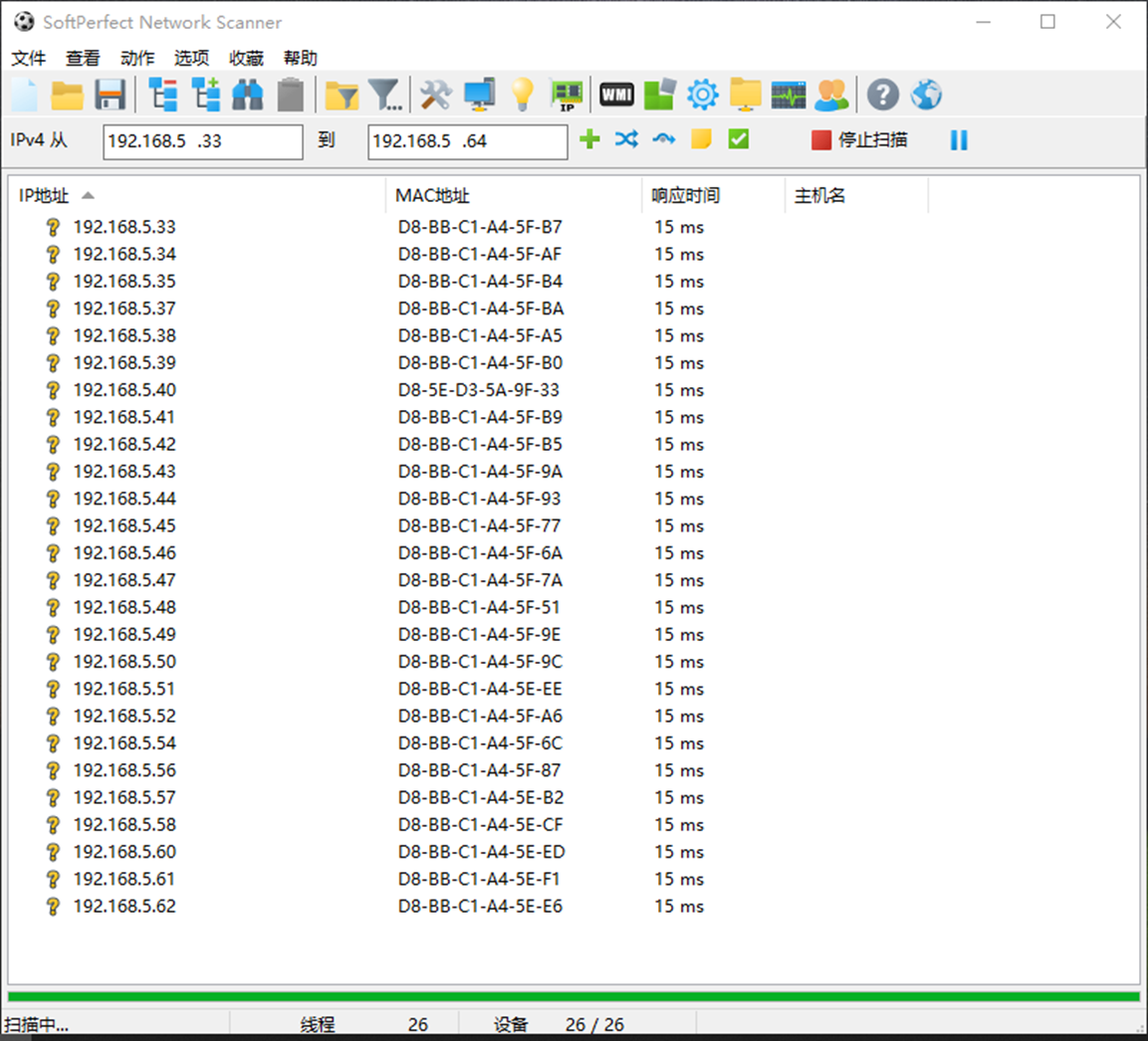

8. Computer management

1. The BIT parameters can be quickly set through the host server, and there is no need to set each computer on site, and the running status of each host can be quickly set and viewed through the host server

2. The handset only needs an IP address to connect to the host, no KVM switch required, and only one monitor is needed to manage 32 computers

9. Software

1. By default, the monitor only displays the main unit, and when you need to switch to another handset, use Softperfect Network Scanner software to scan and connect.

2.After entering the handset, you can see the aging status of the SSD, Fail or both PASS, red means Fail

3. Support multi-master solutions: Realtek, SMI, and Deyiwei test solutions are easy to switch and quick to update.

A. Server interface

B.Client host interface

C.Handset test interface

SATA SSD test line comparison: estimated by 200K/month test capacity

|

Traditional BIT |

Automated testers |

Advantages of automated production line |

|

|

Layout space usage |

6-8 ports per computer |

24 ports per unit |

It occupies less space, has fewer computers, and is easy to manage |

|

Personnel operation |

7 steps |

3 steps |

The operation is simple, the work is reduced, and only half of the number of traditional testers is required |

|

Labor costs |

0.6 |

0.2 |

70% decrease |

|

Annual labor cost |

300,000 |

130 thousand |

Cost savings of 170,000 yuan |

|

Improve yields |

Manual operation for many times, easy to make mistakes |

Reduce the number of operating steps, fix the test procedure, and reduce human error |

There is less human operation in the whole test process, and the defective rate is prompted by LEDs, which eliminates human misoperation and improves the yield of the product by 99.99%. |

|

Test environment |

It cannot be tested at high temperatures |

High temperature testable |

It can be used for high temperature pressure test to improve product reliability |

|

Capacity expansion |

There are many equipment, many personnel, more land occupation, more links, and poor capacity expansion capacity. |

Less equipment, fewer personnel, fewer links, Strong capacity expansion capacity |

The two machines occupy an area of 4 square meters |

|

Device and software management |

There are many devices, many computers and they are separated, and the personnel operate |

Using server management, 32 computers are updated synchronously, and |

Centralized management, one- time completion and traceability, upgradable, and |

|

alone, which is easy to make mistakes, and cannot be updated synchronously, and each computer needs KVM switching. |

the test software parameters are synchronized and consistent |

high consistency of produced products |

|

|

Jobs and training |

7 operation steps, every detail to be trained. |

3 steps, fast training, fast start |

Good management, good training, one-click testing, reduce human error, improve quality |